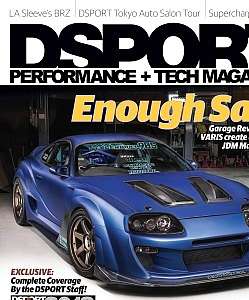

L.A.SLEEVE’s 500whp BRZ Build

New Territory L.A.SLEEVE's BRZ Build

Text by Bassem Girgis and Cameron Parsons -- Photos by Joe Singleton. Courtesy of DSport Magazine.

IF YOU DECIDE TO DO IT, DO IT RIGHT! WHEN it comes to demo-cars, companies cannot afford to cut any corners. Such builds are made to be the cutting-edge of what can be done with that platform. There are no limits. Every part for that car is intended to be the best one possible, showing that the company is only in it to outdo everyone else's build. To display the essence of its business, L.A.SLEEVE asked DSPORT to build a demo-car that will represent them properly. L.A.SLEEVE has been in the business of sleeving engines for both performance and repairs for over seven decades. To truly show what the performance side of their business is all about, a stock 2015 Subaru BRZ was the car of choice, but the word "stock" was soon to vanish from the conversation.

Star of the Show

On the main stage at Club DSPORT, the stock BRZ had a fresh FA20D. Many have argued that the 2.0-liter motor is rather weak in its stock form. The FA20 delivers 170 horsepower and 150 lb-ft of torque, which makes the 2,800-lbs car more of a momentum car. Momentum is not what we are looking for, however, and since the L.A.SLEEVE build will serve as a demonstration of power and capability, we had to take the BRZ to completely new heights and force some much-higher power out of it.

The Goals

L.A.SLEEVE intends for its BRZ to provide more than 500 horsepower out of a built and supercharged FA20. In issue #187, "Stop the Swap," we focused on the FA20 and why you should consider rebuilding one of these engines instead of performing a motor swap. While tuners have chosen to swap the 2.0-liter engines with everything from an LS to a 2JZ, and even a Ferrari 458 engine; we decided to stay loyal to the FA20. The goal is to build a complete, powerful BRZ that can not only reach the 500whp mark, but to also handle just as well. So, before starting on the engine, we turned our attention on the chassis, suspension, and brakes with the help of Peter Yeung at LMR Development to better handle the increased engine performance.

THE GOAL IS TO BUILD A COMPLETE, POWERFUL BRZ THAT CAN NOT ONLY REACH THE 500WHP MARK, BUT TO ALSO HANDLE JUST AS WELL.

Our dyno testing of a Club DSPORT built FA20 has shown that our goals are achievable when using a turbocharger. Now, we propose a supercharged 2.25-liter FA20 that is both powerful and durable.

Staying Grounded

For any well-built demo-car, the goal is not to show how fast the car can go from 0 to 60 mph. The goal is to show how complete the car is. We will be increasing the engine power by almost three times that of stock, which means we had to lower the car's height to improve its center of gravity and improve transitional weight transfer rates under various racing driving modes. Whiteline MAXG were chosen for our coilovers. The MAXG offer 30-60mm height adjustment for both the front and the rear, allowing us to control the height for various racing needs. The coilovers feature a 44.5mm diameter damper bore, which eliminates bending due to the increased surface area loading. The extra width on the dampers strengthen the hardware, enabling them to withstand higher lateral forces during hard corners. This also comes with the benefit of heat-dissipation characteristics to keep the shocks performing reliably and consistently.

The MAXG coilovers from Whiteline were chosen for their ability to maintain suspension geometry under heavy lateral and braking loads on the track without being overly stiff when driving on the street.

Tight Handling

In order to improve the suspension further, we had to get rid of the factory bushings. The stock bushings are made from fairly soft rubber that serve the stock car well, simply incorporated to absorb the energy transmitted from the road to provide a comfortable ride on the streets. However, as the engine power increases, we have to anticipate the high speeds and quick maneuvering. We replaced the stock bushings with ones from Whiteline. The more race-ready bushings reduce slop and flex where various suspension components interconnect. This improves responsiveness, gives better road feedback to the wheels and the driver's seat, and offers greater durability than the stock rubber bushings.

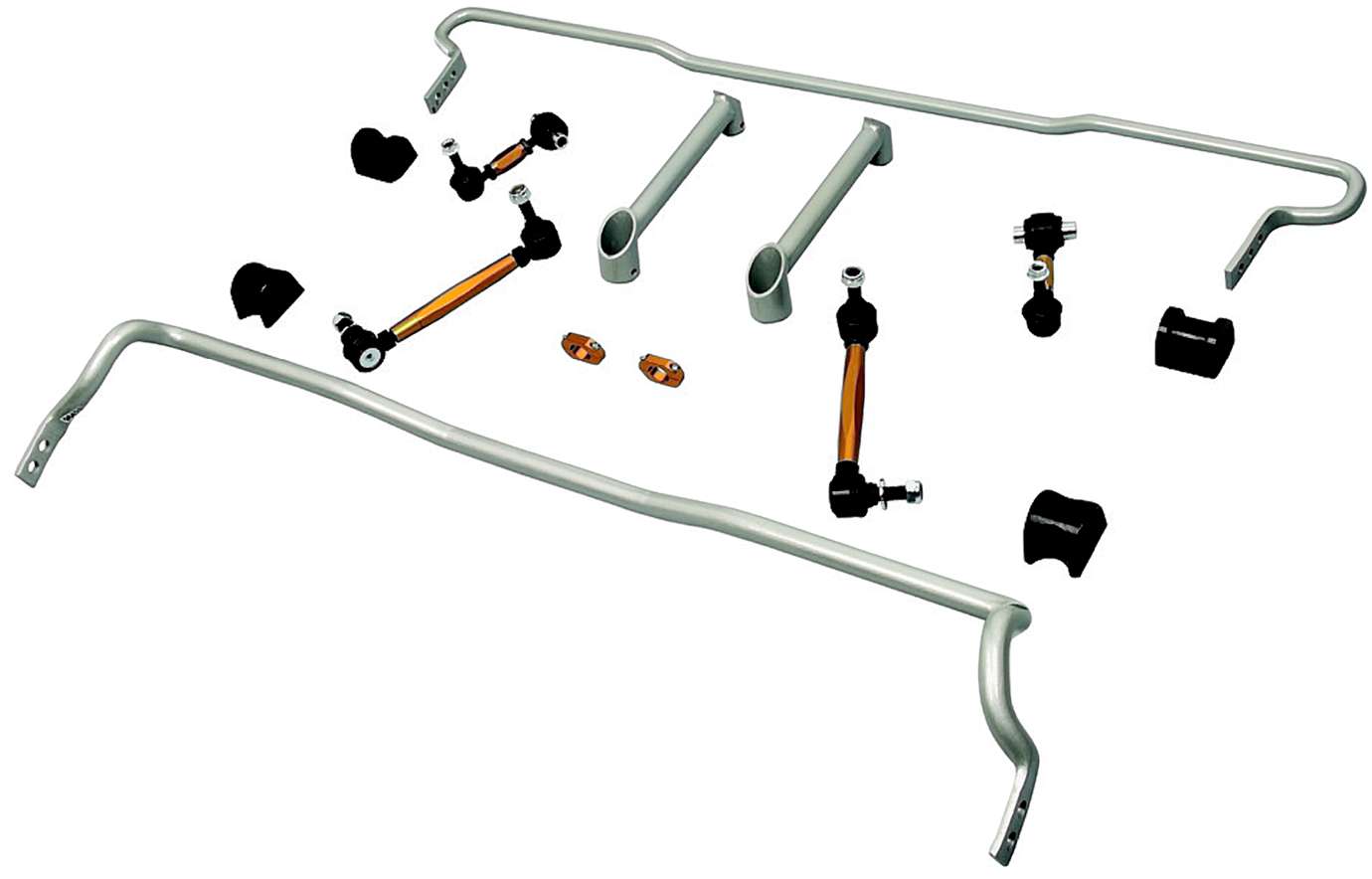

The front and rear adjustable swaybars increase the BRZ's road holding ability without impacting comfort. Rear support braces increase the stiffness of the swaybar mount for increased strength and durability.

WITH THE SUSPENSION UPGRADED TO SUPPORT THE 500 HORSEPOWER GOAL, THERE WERE ONLY A FEW THINGS LEFT TO DO BEFORE WE TURN OUR ATTENTION TO THE ENGINE PERFORMANCE.

As any car increases its speed on track, stability becomes essential. While the front end of the BRZ will be aligned with a small amount of toe-out for improved response, the rear-end needs some toe- in to keep the car stable at high speeds. Whiteline KTA147B rear toe arms replaced the factory arms, allowing for precise toe alignment to keep the car driving straight when needed. With the suspension upgraded to support the 500 horsepower goal, there were only a few things left to do before we turn our attention to the engine performance.

The rear suspension was replaced with adjustable components from Whiteline. The lightweight rear lower control arms have +/- 2.5 degrees of camber adjustment, while the rear toe arms allow for precise tuning of the toe alignment.

Stopping Power

As for all other components on the car, the stock brake system was designed to support the car well in its stock form. However, with the end goals in mind, we knew we had to completely upgrade the brakes for safety. Stock calipers are structurally not stiff enough for higher line pressure at high speeds, which could result in front-wheel lock. We selected one of the most capable brake systems available for the BRZ: the AP Racing Big Brake Kit by Stillen. The kit comes with 4-piston calipers, which offer consistent clamping pressure across the entire pad area that contacts the rotors, as opposed to a floating piston design. The high temperatures that a 500hp track car can generate will take a toll on stock rotors and pads, this can lead to brake fade and even warped rotors. The larger two-piece rotors that come with the AP Racing kit are just right for the task. The two-piece design is typically lighter than the one-piece rotor design. The rotors are slotted, which direct hot gases away from the pads and the discs' surface. It also wipes excess pad material and debris away, keeping both surfaces smooth and effective. To reduce expansion of the brake lines, we installed stainless-steel lines. The stainless lines improve the pedal feel and consistency, and reduces pedal travel under heavy braking.

Based in the UK, AP Racing has been producing braking systems for all levels of motorsports and the performance industry for over 50 years. ISO 9001 and TS 16949 certified, the commitment to the engineering of brakes for competition and OEM applications is impressive.

The AP Racing Big Brake Kit by Stillen is a 330mmx25mm two-piece rotor design with aluminum hats for superior heat dissipation. A four- piston caliper provides superior, consistent clamping force over the stock braking system. The upgrade has DOT-compliant braided stainless- steel brake lines for improved pedal feel and stiffness.

STOCK CALIPERS ARE STRUCTURALLY NOT STIFF ENOUGH FOR HIGHER LINE PRESSURE AT HIGH SPEEDS, WHICH COULD RESULT IN FRONT-WHEEL LOCK.

| Parts List: | |||

|---|---|---|---|

| Part Name | Brand | Model | Price |

| Big Brake Kit | AP Racing | R/T Front | $3,300.00 |

| Front and Rear Sway Bar Kit | Whiteline | BSK020 | $494.82 |

| Rear Control Arms Upper Inner Bushings | Whiteline | KCA326 | $152.82 |

| Rear Control Arms Upper Bushing | Whiteline | KTA216 | $251.82 |

| Front Control Arm Bushing | Whiteline | KTA147 | $314.82 |

| Front Camber Bolts | Whiteline | KCA434 | $134.82 |

| Gearbox Shift Kit | Whiteline | KCA416 | $35.82 |

| Rear Diff Mount in Cradle Bushing | Whiteline | KDT926 | $31.32 |

| Rear Subframe Mount Bushing | Whiteline | KDtT924 | $116.82 |

| Rear Diff Mount in Cradle Support Outrigger | Whiteline | KDT921 | $116.82 |

| Rear Diff Mount Support Outrigger Bushing | Whiteline | KDT925 | $53.82 |

| Rear Subframe Mount Insert Bushing | Whiteline | KDT923 | $53.82 |

| Crossmember Mount Bushing | Whiteline | KDT922 | $40.32 |

| Coilovers Shocks | Whiteline | MG1-SUB006 | $2,564.99 |

| Total: $7,662.83 | |||

WITH A ROBUST SUSPENSION SYSTEM AND A GREAT BRAKE SYSTEM, WE ARE FINALLY READY TO CONFIDENTLY TAKE THE ENGINE TO NEW HEIGHTS.

Onto The Next Phase

The road to the 500 horsepower L.A.SLEEVE BRZ started with a solid foundation. With a robust suspension system and a great brake system, we are finally ready to confidently take the engine to new heights. To get the engine where we want it to be, we will need to completely disassemble it, precisely machine the block to accept the sleeves, and upgrade the weak-links that will require additional strength and durability. Targeting 500whp with a centrifugal supercharger is a new territory waiting to be explored more, and with our use of the Vortech Supercharger along with the block machining and engine modifications, we are out to prove that the FA20D may be small in size, but it surely is capable.

FA225sc Club DSPORT's Power Solution for L.A.SLEEVE's BRZ Demo Car

Text by Bassem Girgis -- Photos by Joe Singleton. Courtesy of DSport Magazine.

WHILE MANY HAVE ENCOUNTERED CHALLENGES WITH FA20D DEVELOPMENT, we've experienced the exact opposite. Our Club DSPORT FA21D (2.1-liter stroker variant) engines are thriving with turbocharged examples delivering over 560 horsepower to the wheels on E85 or Japanese premium pump gas (98 RON). In fact, Phoenix's Power recently used one of the Club DSPORT FA21D short blocks in a street car to set the top speed record for an 86/BRZ in Japan. While the Club DSPORT FA21D engines use the original 86mm bore size (and no sleeves), Club DSPORT concurrently developed its FA225D engine program that features a sleeved 89mm bore size and the same 90mm stroke. With the custom L.A.SLEEVE amphibian sleeves in place, the power handling of the FA225D exceeds the FA21D (although that limit has yet to be found). The bigger, badder and better FA225 engine will also be receiving a big Vortech supercharger.

PHOENIX'S POWER RECENTLY USED ONE OF THE CLUB DSPORT FA21D SHORT BLOCKS IN A STREET CAR TO SET THE TOP SPEED RECORD FOR AN 86/BRZ IN JAPAN.

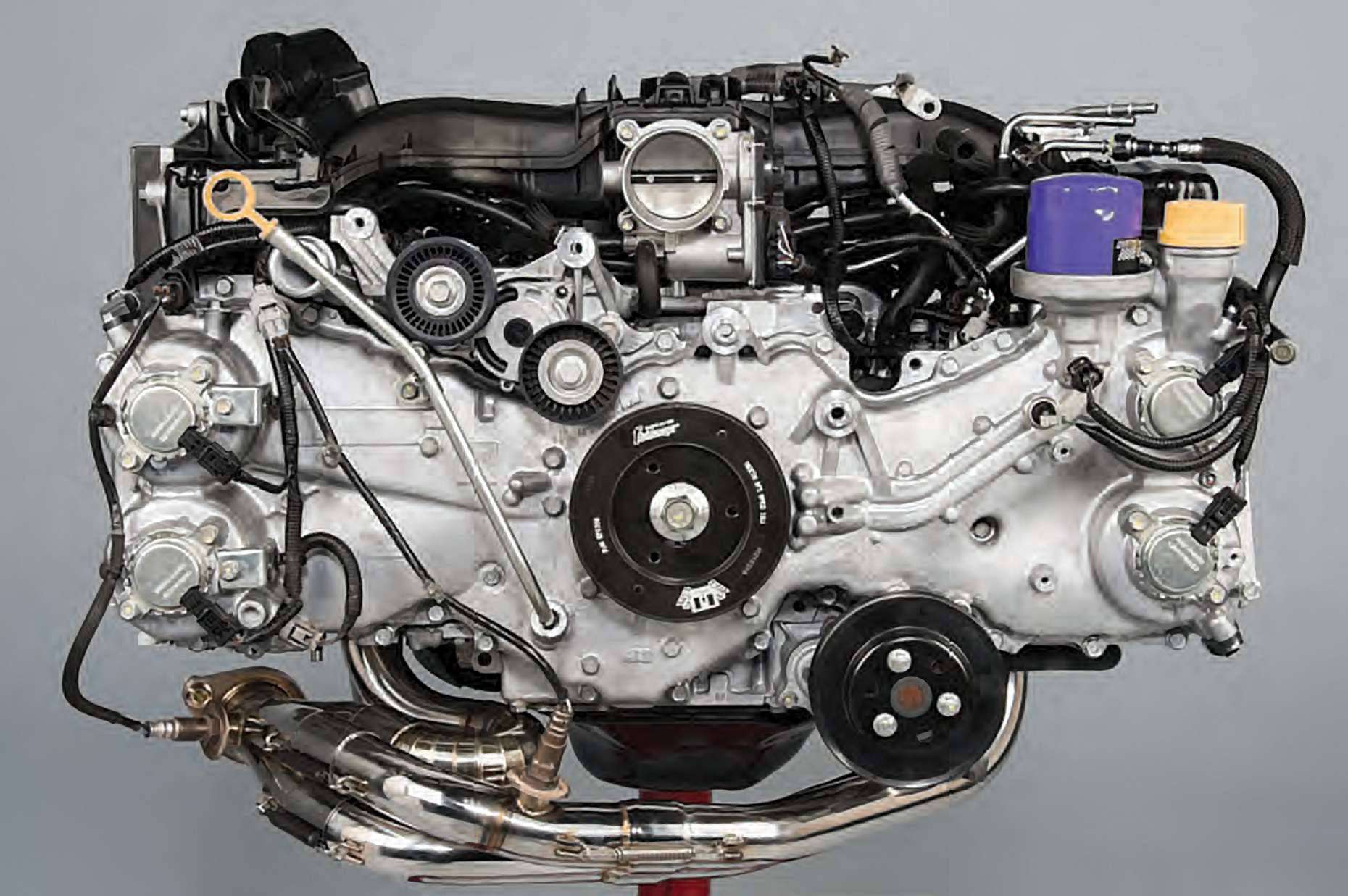

Custom amphibian sleeves from L.A.SLEEVE allow for an 89mm bore. The larger bore is filled by Club DSPORT E85-optimized pistons manufactured by Mahle. ARP fasteners are used to hold the case together at the elevated power levels. The right combination of parts along with precision machining and assembly deliver a powerful and reliable combination proving itself in all forms of competitive use.

Quick Recap

In part one of the L.A.SLEEVE BRZ demo car build, we upgraded the suspension and brake systems to complement the planned power increase. In the interest of high-speed handling and maneuverability, we adjusted the ride height to keep the car's center of gravity low, equipped it with stiffer MAXG coilovers from Whiteline, replaced the soft factory bushings to reduce slop and flex, and added some more support to the chassis to minimize chassis flex. With the suspension upgrades in place, we installed an AP Racing Big Brake Kit by Stillen to maximize braking capabilities. With the suspension and brakes upgraded and ready to go, it was time we turn our attention to the powerplant that will become the most powerful supercharged FA engine ever.

Club DSPORT FA225sc

Unfortunately, there isn't a week that goes by where we don't hear about someone's "built" FA20 horror story. Some of the major causes of an engine build failure include improper machining, cleaning, and assembly or simply using parts that were not properly engineered. There's blown head gaskets, cracked pistons, high oil consumption and even broken camshafts. The excuses and "solutions" to what is sometimes a bad build or a bad tune are nothing short of comical. But it sucks to laugh at someone else's expense. Fortunately, we've been on the other end of FA20 engine development with our engine packages exceeding our power and efficiency predictions. While we are still planning to push the boundaries, it's safe to say that Club DSPORT has the 560-plus-horsepower FA engine combination figured out. Our solution doesn't rely upon welded-up or machined closed decks, 14mm head studs or other "solutions" that seem to be causing more problems than they fix.

Engineering the Solutions

Our Publisher Michael Ferrara is a Mechanical and Aerospace engineer that's been working with the top manufacturers in the performance aftermarket for the past 20 years. He's already tackled the 4G63, 4B11, RB26, 2JZ, KA24 and SR20 in the past and he loves the challenge a new platform brings. Engine development is his passion. Having Master Machinist and F1-experienced Engine Assembler Magnus Ohlaker as part of the team has made unlocking the secrets of the FA20 platform a pretty straightforward affair. After all, few can claim to building over 400 Subaru EJ25 engines in their lifetime. For the FA20 development, Michael and Magnus looked for the weak links and opportunities presented in the platform. This is what led to the parts that Club DSPORT developed and selected for the Reference Series builds.

WITH THE ADDED THICKNESS AND HIGH STRENGTH OF THE SLEEVES, THE ENGINE CAN BE PUSHED FAR PAST THE FACTORY SPECIFICATIONS.

Machining & Assembly

One of the shortfalls in the Subaru engine is a lack of precision with regards to the machining process. While the level of precision is fine for stock power outputs, generating two to five times those levels requires a higher level of precision.

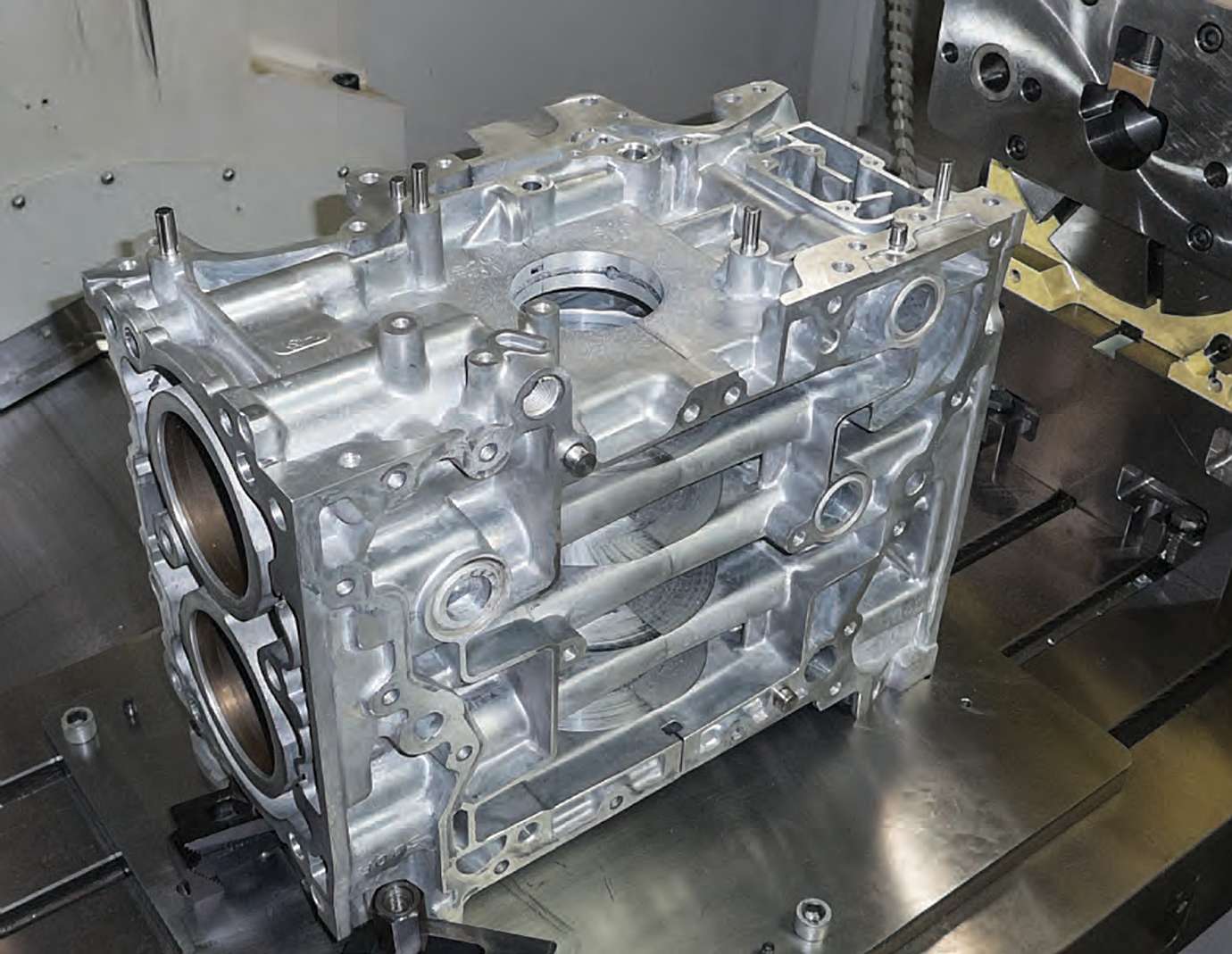

For the Club DSPORT FA225, L.A.SLEEVE manufactured custom thick-wall amphibious cylinder liners.

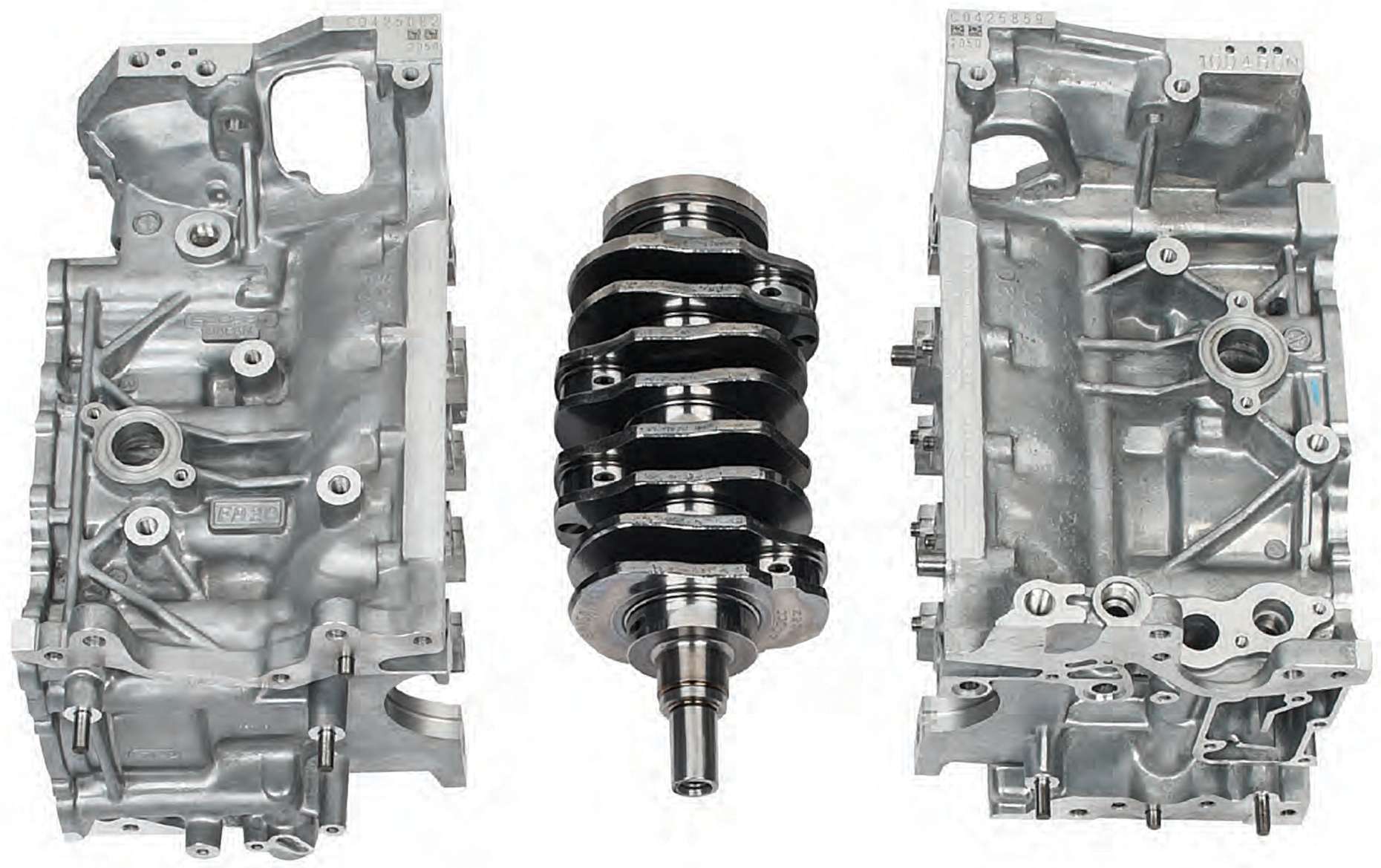

Nearly all Subaru boxer engines have a crankshaft centerline that simply isn't straight in the block. As a result, the crankshaft lays to the left or the right or up or down at the front or the rear. This misalignment can place additional stress on the case halves at higher power levels. Since the amount of bearing surface area is relatively small, this can also accelerate bearing wear.

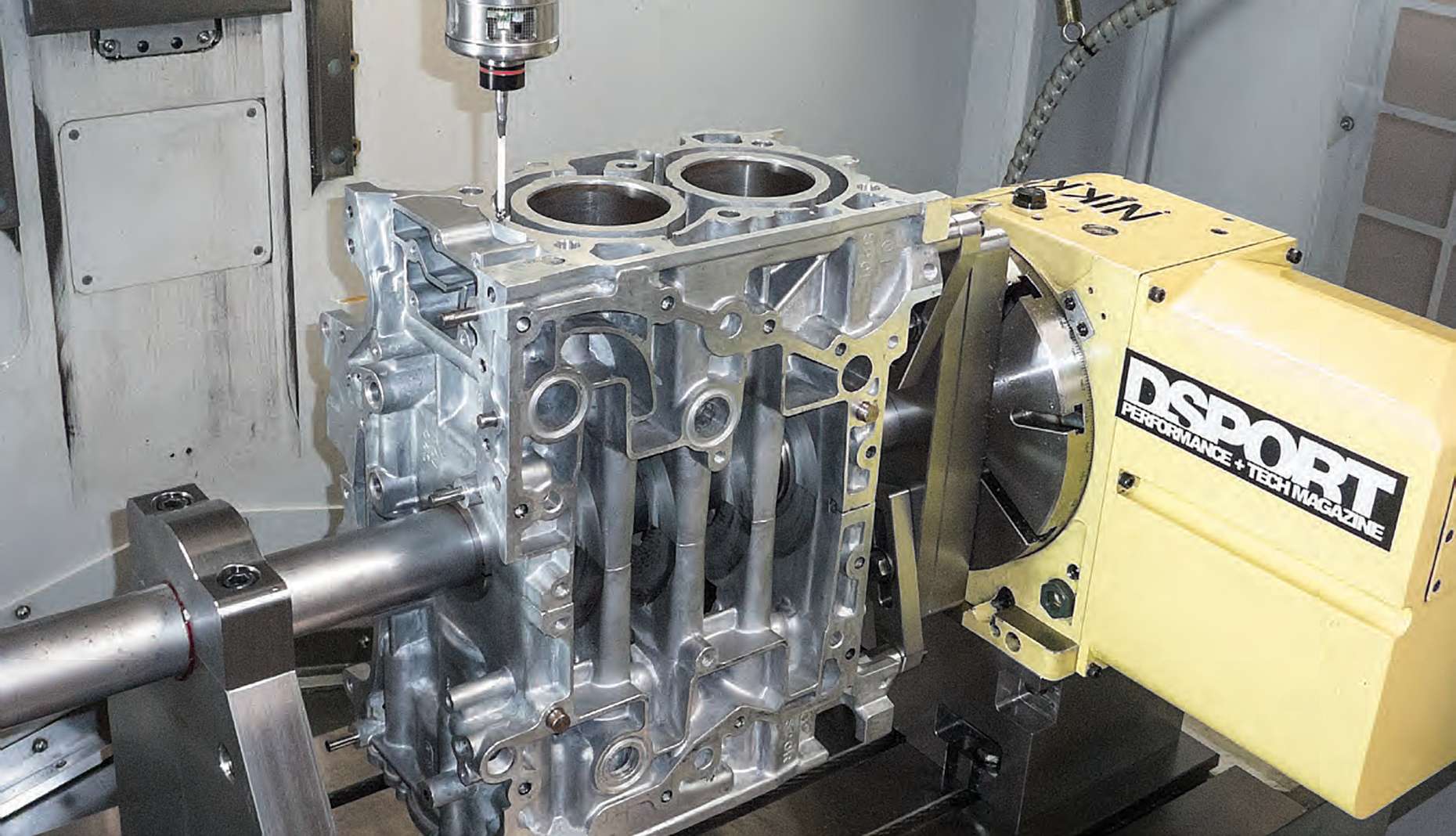

The first operation performed at Club DSPORT on all FA20 engine builds (new or reconditioned blocks) is to correct the main bore on the block. To accomplish this, both of the case halves are decked flat removing between 0.001"~0.002" (25-to-50 microns) on the CNC mill using a PCD insert. This process leaves a superior finish and allows for a new bore to be made at the tight tolerance of the OEM spec for the main housing bores. Once decking of the case halves is completed, the case is reassembled with ARP case bolts and torqued to the recommended spec. At this point, the assembly is placed on the Club DSPORT CNC line boring fixture where about two hours is spent to ensure that the engine case is lined up before the boring of the mains take place. A special PVD insert is used to machine the main bearing housing to leave a superior finish. Once the operation is completed, the case is taken apart so that the 2.0000-inch main bar can be installed with the precision main bore rings into the block. After this procedure, the block is ready to get some 4-axis CNC operations.

4-axis CNC Time

A probing operation is performed to establish the deck and cylinder locations of the block. As the block is on a rotary, it's easy to rotate the block exactly 180 degrees to ensure that operations remain symmetric as needed. The first operation matches the deck heights of both sides of the block by taking the absolute minimum amount of material from the deck surfaces. This operation ensures that both banks of the block will have identical piston-to-deck clearances and compression ratios.

ONCE ALL FOUR CYLINDERS HAVE BEEN BORED AT THE EXACT LOCATIONS, THE BLOCK IS ONE STEP CLOSER TO GETTING THE SLEEVE INSTALLED.

For a Club DSPORT FA21 engine, the process on the 4-axis CNC would be done, but when sleeving is to take place, the FA225 engine will have two separate visits to the 4-axis CNC. On the first visit, the OEM cylinders will be bored out to roughly 95.25mm to fit the new sleeves. The exact dimension depends on the exact dimension of the sleeves. The block will actually be bored slightly smaller than the OD of the sleeves. The smaller bore dimension in the block versus the outside diameter of the sleeve will provide an interference fit. The finish of the bore in the block is one area that can affect the success of the sleeving operation. The bore itself must be round and taper-free with a finish as smooth as possible. This is accomplished by running an optimized speed and feed with a PVD insert to cut the aluminum. Once all four cylinders have been bored at the exact locations, the block is one step closer to getting the sleeve installed so that they can be decked and bored to the target size.

OUR GOAL WAS TO BOTH INCREASE THE BORE SIZE (FROM 86 TO 89MM) AND TO INCREASE THE STRENGTH OF THE CYLINDERS.

Engine sleeving is used as a method to either repair a damaged cylinder, increase the maximum bore size, or to simply strengthen the engine when higher power is desired. Our goal was to both increase the bore size (from 86 to 89mm) and to increase the strength of the cylinders. L.A.SLEEVE manufactures custom sleeves constructed from Moly 2000 ductile iron to fit any engine. With the added thickness and high strength of the sleeves, the engine can be pushed far past the factory specifications.

Dry ice cools the ductile iron sleeves to -109° F, shrinking their size. As a result, they can be slipped into the heated 220° F engine block for a precise interference fit.

Fire & Ice

We chill the sleeves in dry ice to shrink their outer diameter, while heating the block to 220 °F to allow the bores to expand for a smooth installation of the sleeves. Once the sleeves were in place, we installed a torque plate to simulate the head, and torqued it to the correct specifications. A heat cycle regiment allows the sleeves to settle in their new home. The sleeved block is then placed back into the 4-axis CNC to be bored within a few thousandths of an inch of the final size while the sleeves are decked to their final height.

The bores are plateau honed for optimum surface profile and cylindrical roundness.

Finally, with the torque plate still in place, we honed the cylinder sleeves to the final dimension, with just a few tenths of a thousandths of an inch accuracy. The correct angle cross-hatch pattern and surface finish is critical for proper seating of the piston rings and cylinder lubrication.

Bottoms Up: The Right Parts

For the Club DSPORT FA225 builds, we source brand-new FA20D bare blocks from Heuberger Subaru of Colorado Springs, Colorado. These blocks go through a number of machining operations before the custom L.A.SLEEVE amphibious sleeves are installed. To fill the sleeves, the pistons were engineered in cooperation with Mahle Motorsports. Machined from M142 forged aluminum alloy, the greater strength, lighter weight and thermal stability of the forging is ideal for high-performance and extended durability. The pistons have a revised compression height and ring package location to compensate for the 90mm stroke crankshaft and custom rod length. The piston's top ring grooves are hard-anodized, which protects against micro-welding and further increases the pistons' strength and resistance to failure of the ring land. The pistons go through a triple-coating process with a phosphate dry film to protect the pin bores from galling, as well as having Mahle's proprietary anti-friction coating applied to the skirts. With the higher temperatures and pressure in the cylinders from the boosted engine, it is crucial for the piston to be strong and durable without adding unnecessary mass. The secret to the exceptional combustion performance from these pistons lies in the geometry of the piston dome. Since Mahle is the piston supplier to a number of OEMs that manufacture direct-injection engines, they are no strangers to the geometries that can deliver exceptional performance and reduce the likelihood of detonation. The pistons yield a final static compression ratio between 10.8~11.0:1 on BRZ/FR-S/86 engines or an 11.0~11.2 compression ratio on WRX FA20 engines (due to the smaller combustion chamber on the turbo cylinder heads).

With the sleeves installed and bored in the cylinders, they are decked to achieve the final height.

Since the Club DSPORT FA21 and FA225 engine packages use a Club DSPORT-spec forged-steel 90mm stroke (+4mm longer than stock) crankshaft, a connecting rod needed to be engineered with new measurements and the power handling capability of 1,000whp. Club DSPORT engineers worked with Manley Performance to produce a custom Turbo-Tuff 4340-alloy, USA-manufactured custom high-performance rod as the solution. This rod features ARP rod bolts and the unique cap design present on FA20 engines. The design of the rods maximizes the strength without requiring any clearancing of the engine block. ARP also provides the solution for the high-performance fasteners used for the case and the cylinder head.

THE PISTONS HAVE A REVISED COMPRESSION HEIGHT AND RING PACKAGE LOCATION TO COMPENSATE FOR THE 90MM STROKE CRANKSHAFT AND CUSTOM ROD LENGTH.

A quality bearing is imperative when building a high-output engine, both for performance and longevity. For these reasons we chose King Racing Bearings. To absorb vibration and protect the crankshaft, we installed a Fluidamper harmonic damper.

In the interest of maintaining a proper equilibrium, we balanced our crankshaft, pistons, pins, and rods in a dynamic three-stage balancing process to within 0.25 grams. As an engine's speed increases, any imbalance is magnified; the force exerted on the main bearings is relative to the RPM of the engine squared. Balancing the reciprocating and rotating mass reduces vibration and increases the lifespan and power output of the engine.

The ARP case bolts are constructed from 8740 chrome moly. The performance studs are required to ensure the case halves don't shift under higher power, which can cause bearing or crankshaft wear.

A three-angle valve job was completed before the installation of the Supertech valves and a set of Piper Cams springs. The heads, sourced from Heuberger Subaru, were then attached using an ARP head stud kit.

Top-End: Heads, Cams & Valvetrain

The camshafts are responsible for the opening and the closing of the valves, which means they control the air, fuel (from port system), and exhaust flow going in and out of the engine. To optimize volumetric efficiency, we selected Piper Cams BP285 bumpsticks (Stage 3). These camshafts are designed for the ultimate road/track day car, which made them the perfect fit for L.A.SLEEVE's demo-car. They offer a cam profile that delivers mid-range torque and top-end power, without sacrificing the idle and low-load characteristics needed on a mild-mannered street car. The camshafts work collaboratively with a spring and retainer kit from Piper Cams. Even the smallest component can play a huge role in an engine's performance. The valvetrain can be a major factor in regards to an engine's airflow, mixture quality, and high RPM efficiency. The design, shape, and seat angle of a performance valve is engineered to maximize the flow and velocity of the gases going in and out of the combustion chamber. The valve is only open for a brief moment, then it must snap shut to form an effective seal. We chose Supertech intake and exhaust valves to help us reach our goal. The intake valves are stainless steel with a black nitride coating that hardens the surface of the valve. The exhaust valves are constructed from inconel 751 alloy steel. The light weight and extreme heat-handling characteristics are ideal for our soon-to-be supercharged application. Only the exhaust side requires the higher heat-handling characteristics of the inconel alloy. The heads were ported at Club DSPORT to eliminate any additional restrictions in the airflow before a fully-radiused valve job was performed on the Newen.

IF YOU'VE EVER FELT LIKE THE BRZ IS A BIT UNDERPOWERED, L.A.SLEEVE'S DEMO-CAR WILL MOST CERTAINLY CHANGE YOUR MIND.

The Subaru boxer engine is a horizontally-opposed configuration with the cylinders placed on opposite sides of the crankshaft in two separate case halves.

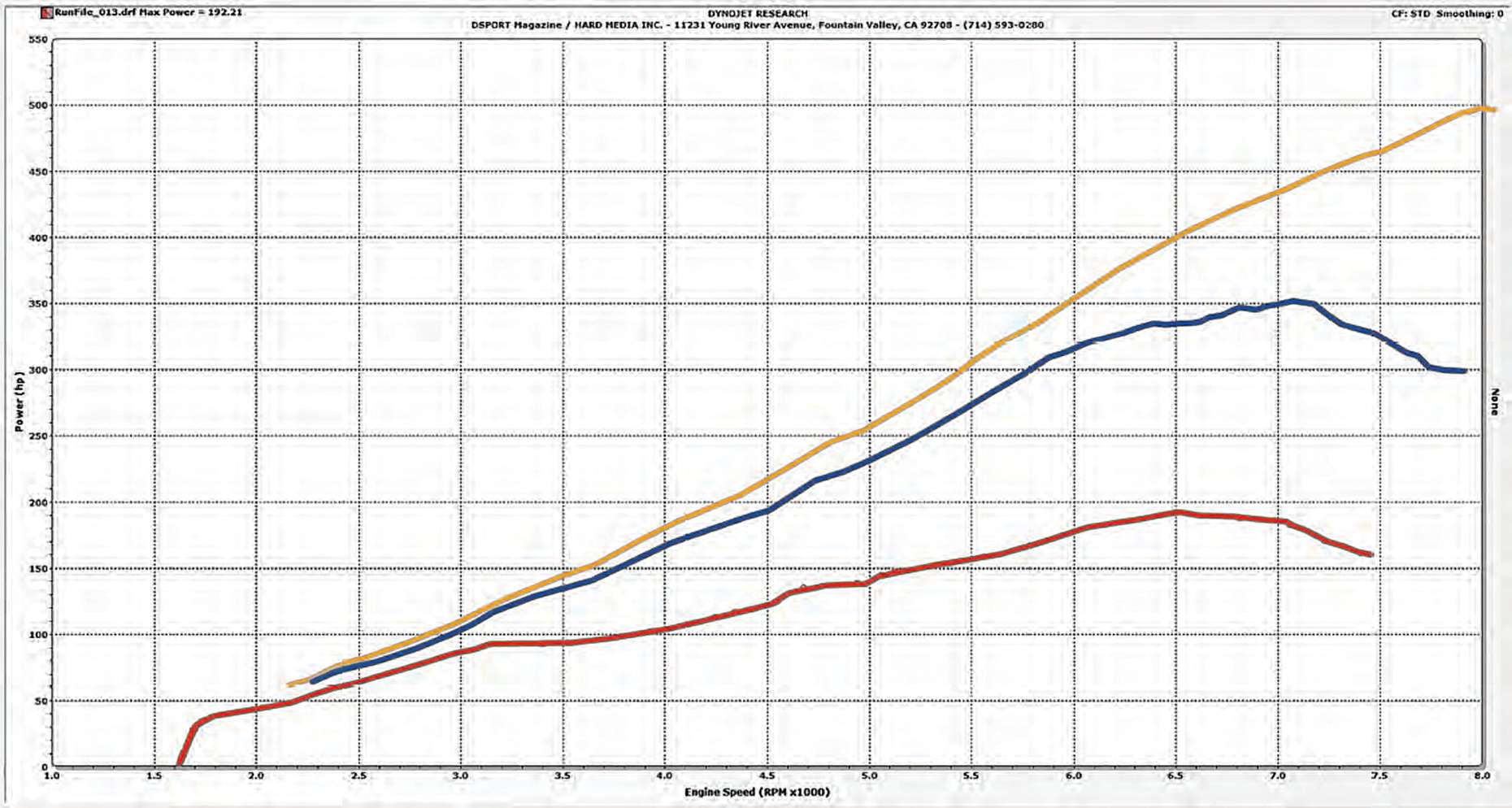

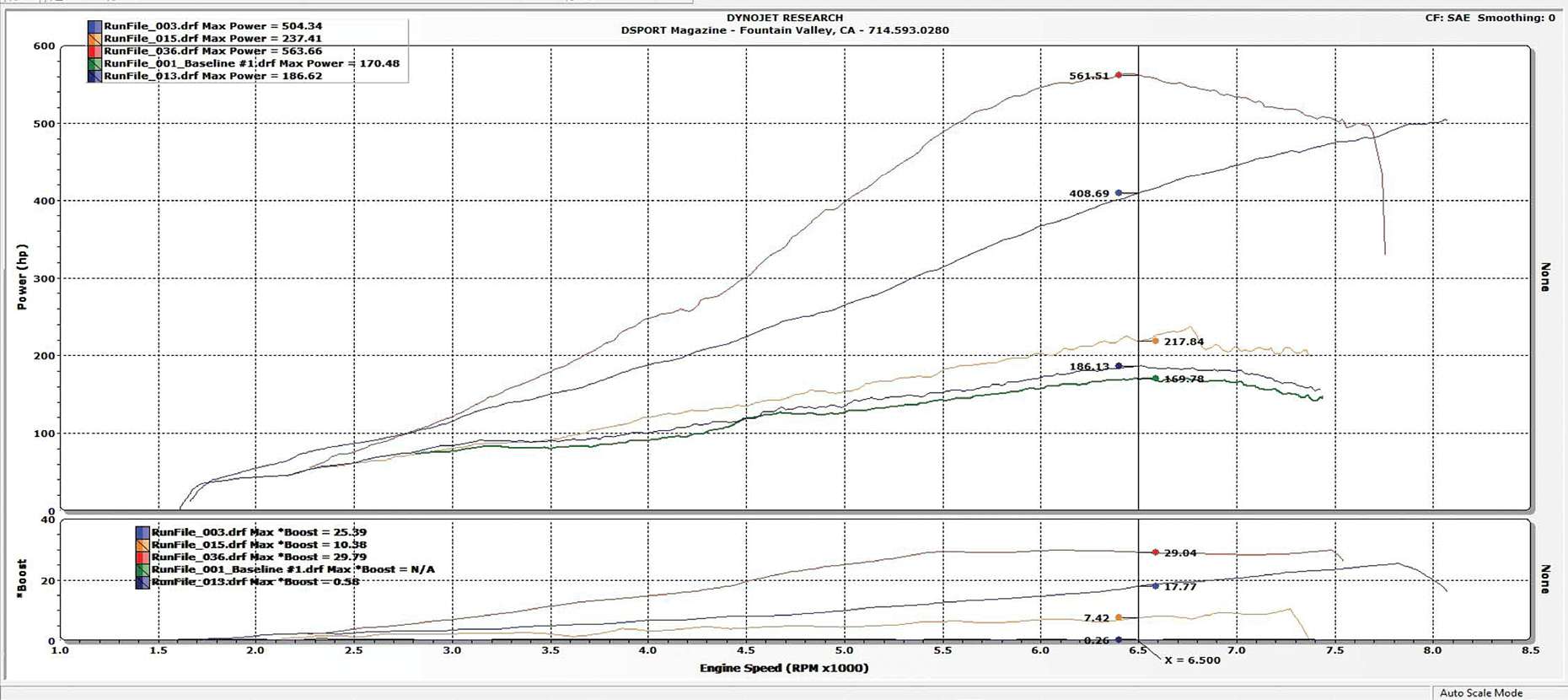

- – 500HP E85 TARGET

- – 350HP 91-Octane

- – 190HP No S/C

The red line shows the pre-supercharger output of the FA225 engine with OEM intake, exhaust and ECU in place. This was done for a quick and simple break-in. The blue and yellow lines represent the power goals for the Vortech-enhanced FA225.

It's Almost Time

With our FA225 completed, installed and broken-in (without the supercharger in place), we have netted 190 horsepower to the wheels with all of the factory components in place (headers, exhaust system, intake, etc.). Next, we look forward to the addition of the blower and complementary items, like the fuel system, the cooling system, and the flex-fuel electronics. Our target is to make over 350whp on 91-octane and to hit 500whp on E85. If we can do it, we will hold the title of world's most powerful supercharged FA engine. If you've ever felt like the BRZ is a bit underpowered, L.A.SLEEVE's demo-car will most certainly change your mind.

| Parts List: | |

|---|---|

| Part Name | Brand |

| Piston: | Club DSPORT by Mahle |

| Crank: | Club DSPORT 90mm |

| Rods: | Club DSPORT by Manley |

| Rod Bolts: | ARP2000 or CA625+ |

| Rod Bearings: | King Bearing |

| Engine Bearings: | King Bearing |

| Head Studs: | ARP |

| Main Studs: | ARP |

| Damper: | Fluidamper |

| Camshafts: | Piper Cams |

| Springs and Retainer Kit: | Piper Cams |

| Valve Guides: | Supertech |

| Intake Valve: | Supertech (35mm) |

| Exhaust Valve: | Supertech +1mm (30mm) |

| Valve Steam Seals: | Supertech |

Now the World's Most Powerful Supercharged BRZ L.A.SLEEVE's BRZ Build

Text by Michael Ferrara -- Photos by Joe Singleton. Courtesy of DSport Magazine.

WHEN L.A.SLEEVE TASKED US WITH BUILDING A COMPANY demo car that would have broad appeal, the Scion FR-S/Subaru BRZ/Toyota 86 platform was the obvious choice. The aftermarket support for these models is second to none. It's a great platform that can be made to do just about anything. When L.A.SLEEVE also asked us to make the project both unique and impressive, that's when things got interesting.

Let's Force It

While we could have explored building an all motor FA20 engine, a great deal of effort and expense may have resulted in a 2.25-liter FA20 engine that makes 200 horsepower at the wheels on E85. That wouldn't cut it, especially considering that any of the off the shelf forced induction options would produce more power at less expense. Boost would be part of the equation.

Turbo or Supercharger

Since we have already tested just about every supercharger and turbocharger system available for the BRZ/FR-S/86, we already had an idea of what to expect. With a turbocharger and one of Club DSPORT's 2.1-liter stroker engines, we had already realized over 480 lb-ft of torque and over 560 wheel horsepower on pump E85 when running about 29psi of boost. We first considered a big bore, stroker FA22.5 (2.25-liter) engine teamed with a turbocharger. The additional displacement of the engine would have allowed peak boost to be realized at about 4,900RPM with the same turbo with torque peaking at about 515 lb-ft at the same boost level. Since the engine would have increased power handling due to the L.A.SLEEVEs, we could also run a larger turbo to make 600, 700 or 800whp. However, we then considered the power handling of the driveline. Currently we don't have a transmission solution for our 2.1-liter FR-S turbo that we trust to track or drag. There is no way the factory transmission can live when the torque output is nearly four times the original output of the engine.

Ruling out a turbocharger system meant a supercharged solution was in order. There are basically two types of superchargers: positive displacement and centrifugal. The Edelbrock, Innovate, Sprintex and Cosworth supercharger systems rely upon a positive-displacement supercharger. The Vortech, Kraftworks and HKS systems use a centrifugal supercharger system. All of these superchargers are driven by a belt system from the crankshaft. Some of the systems offer intercoolers allowing for additional power and reliability, some do not. Both types of superchargers have their pros and cons. For a given power output and boost level, a positive-displacement supercharger will generate more torque at the lower engine speeds compared to a centrifugal supercharger. On the contrary, a centrifugal supercharger will sacrifice some low-end torque in order to deliver a more efficient airflow at lower outlet temperatures while also requiring less power to drive the compressor.

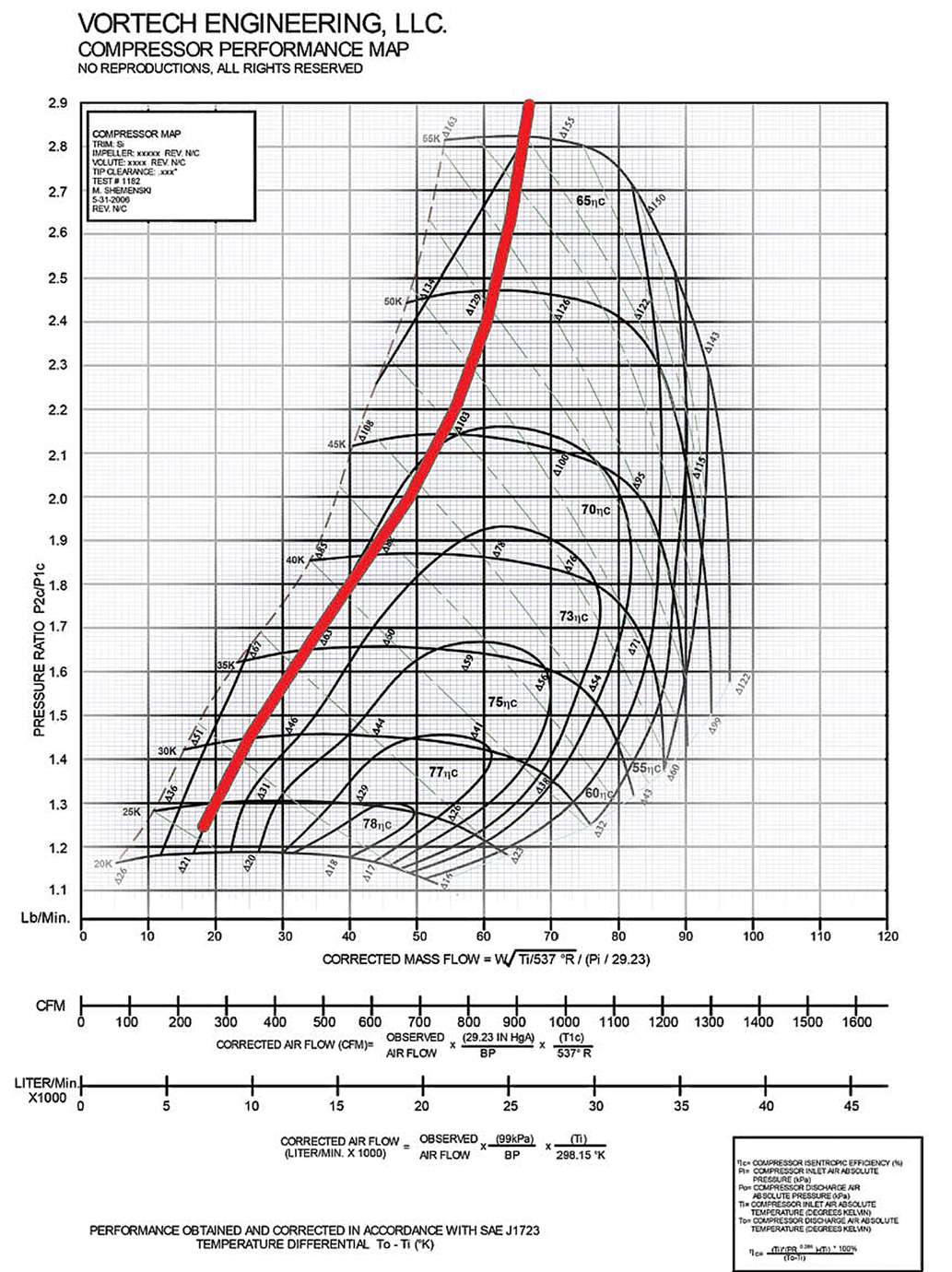

At the end of the day, our decision for which supercharger system to run was made easy.Only the Vortech V3Si supercharger was theoretically capable of the 500whp target, although no one had done it yet.

Normally a fuel system capable of supporting 500whp on E85 requires some custom lines and a good amount of time. Thanks to Radium Engineering, everything we needed was available as a bolt-in solution.

Building the System

While Vortech offers the bracket, pulley and V3 Si supercharger for the BRZ/FR-S/86, they don't offer an intercooler system for that power level. Since we already knew that the intercooler system used with the Full-Race turbo system could support the flow and cooling needed at 500whp, we opted to use it with our Vortech V3 Si setup. To use this intercooler with the Vortech supercharger required some custom charge pipes be made and that a Vortech Maxflow Race blow-off valve be fitted on the compressor outlet charge pipe. Since the V3 superchargers have a self-contained oiling system, there was no need to plumb a pressurized oil feed or drain to the engine. If you don't mind the added complexity of installing a feed line and drain, a V-1 H/D Si supercharger can be chosen instead. This option is rated a slightly higher recommended maximum speed(55,000 RPM vs. 52,000 RPM), but it will run a bit slower as the internal gearing features a lower step up ratio.

Since the Vortech V3-SERIES superchargers have a self-contained oiling system, there was no need to plumb a pressurized oil feed or drain to the engine.

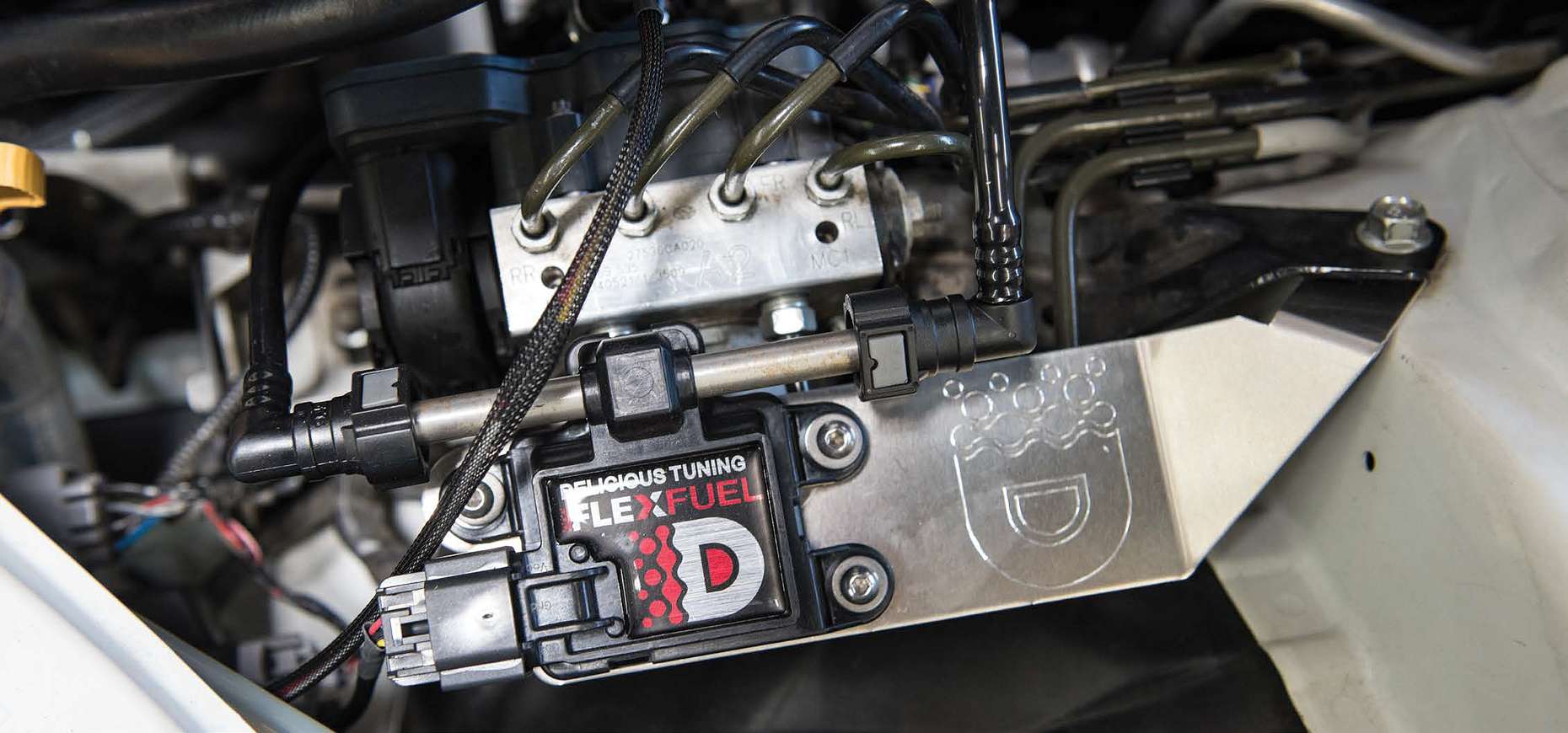

Fueling the Beast

The fuel demands of a 500whp engine on E85 are the same as a gasoline engine at 735whp. It's a pretty high demand especially when you consider that the pump will be operating at about 80 psi to overcome the rail pressure, boost pressure and pressure losses in the system. Normally planning out a bulletproof system would require a great deal of fabrication.Fortunately, everything that was needed was available off the shelf from Radium, Walbro and AUS Injection. Radium supplied the dual pump hanger kit, dual pump wiring kit, fuel line kit and fuel rail for the Walbro 340lph pumps and 1150cc/min injectors from AUS. While we tested the system on the dyno with a single pump and proper fuel line pressures were maintained, employing a second pump erases any doubt that there will be ample pressure regardless of the on-the-track conditions.

The twin fuel pump hanger from Radium Engineering holds one or two Walbro 340lph fuel pumps. We verified that a single pump can handle the power level on the dyno, but a second pump is good insurance on the track.

AUS Injection supplied a set of 1150cc/min injectors to send the necessary aditional fuel to support over 500whp on E85.

Exhaust and Cooling

While getting 500whp worth of air and fuel into the engine is important, getting 500whp worth of exhaust and waste heat out of the engine is equally as important. We opted for a BLOX Racing unequal length stainless header. This stainless steel 4-into-1 header features 1.75-inch primary tubing and a2.25-inch collector. This was teamed with a BLOXRacing overpipe and a BLOX Racing front pipe. The system joins a Full Race 3-inch cat-back exhaust system. With all of the factory cats eliminated in this configuration, the setup is only for the racetrack. As for the sound levels associated with this configuration…it's somewhere between deafening and torture. This is one area we hope to address in finding a more streetable and ear-friendly configuration.

While the Mishimoto oil cooler systems provides a mounting and hose solution for a stock application, we mounted the cooler on the Full Race front bar.

While the exhaust helps carry much of the waste heat out of the engine, the cooling system also needed upgrades to reject additional waste heat. A drop-in Mishimoto radiator and fan shroud kit have kept things cool during all of the dyno testing, while a Mishimoto oil cooler should keep oil temps in check when this BRZ visits the track.

Since a turbo system would make too much torque for the stock transmission, we needed to hit our power target with the least amount of torque output possible. As a secondary benefit, a more reasonable torque output would also reduce the likelihood of wheel spin.

The Full-Race front mount air-to-air intercooler proved to be effective when previously used with a Full-Race turbo kit to support over 565whp. We teamed it with a custom Vortech V3 Si supercharger and Voretch Maxflow BOV.

Dyno Challenges

We started the dyno testing on 91-octane and the largest pulley (3.48-inch OD for lowest boost). When we hit 305whp at 7,000RPM (10.5psi of boost), we didn't know if we should be concerned or celebrating. On the one hand, this was considerably better than the 232whp realized on the standard Vortech kit at 8psi. On the other hand, it was just 60percent of our target power. It was time to try some smaller pulleys and see the results.With the 2.87-inch pulley in place, power climbed to 339whp, with boost checking in at 14psi. The smallest 2.62-inch pulley netted 364whp and just 16psi of boost pressure. Things didn't seem to be adding up. We should have been making considerably more boost based on the pulley ratios.

The red line represents the points on the compressor map we are hitting. The V3 Si compressor is really optimized for engines making about 250~450whp to start. Since this engine only makes 185whp without boost, it doesn't get to run in the highest efficiency ranges possible. Still, it's currently the best fit of the currently available compressors.

Delicious Tuning did all of the engine ECU calibration via the ECUTEK. Tuning was done on both 91-octane and pump E85.

The following day we opted to switch to E85 to see if the91 octane was the limiting factor and to also try a GatesRPM supercharger belt instead of the standard Gates belt supplied. While you should never change two variables at once if you want the best data, we were driven by the fact that we were so far from our target. This session netted some more encouraging results. Power now reached a peak of 471whp with boost checking in at 24psi. Belt slippage was significantly reduced as we could see the difference in the boost curves before and after the change to the RPM-series belt (we consider this a must for any supercharged application). While promising, we were still29 horsepower shy of our goal. We could have cheated and set the dyno reading to STD instead of SAE then said that 485whp is close enough. We didn't. This challenge and opportunity would instead serve to broaden our knowledge.

The true dual muffler exhaust from Full-Race is currently part of the "it's too loud" race-only exhaust. Hopefully, it will quiet down with the cats back in place.

To further limit belt slippage, we ordered a shorter Gates RPM belt (hopefully adding some tension) and we also sent a set of pulleys out for Carbonite treatment. This treatment roughens the pulley surface to aid in limiting slip. Why is slip such an issue?Let's not forget that the Vortech supercharger is a compressor. It's moving about 1,000cfm of air at a peak pressure ratio of 2.7:1 (27psi before intercooler). That takes somewhere in the neighborhood of 80 horsepower of work to accomplish. While we plan to expand on the belt and pulley treatment data next month, the bottom line is that we were able to produce 504whp at 25psi of boost. Mission accomplished.

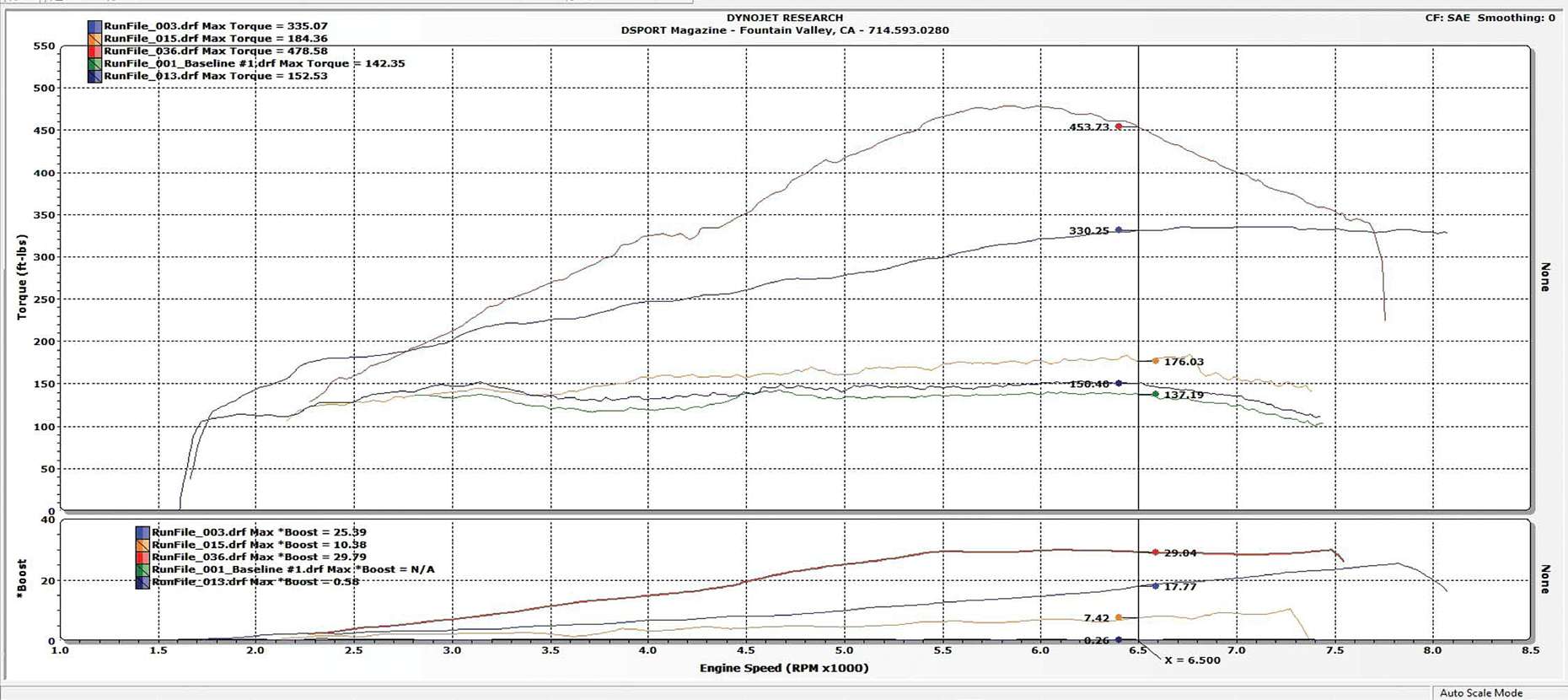

The flat torque curve delivers between 300 and 335 ft-lbs of torque between 5,500 and 8,000RPM. THIS is ideal for transmissionS that have limited torque handling capabilities.

- – 185 ft-lb Vortech Stock

- – 335 ft-lb Vortech V3 Si 2.25L

- – 485 ft-lb Turbo 2.1L

At max boost, the torque possible from the Full-Race turbo on a Club DSPORT 2.1L is more than the factory transmission can handle. The CARB-legal Vortech supercharger system takes peak torque up from 142 to 184 ft-lbs. For the L.A.SLEEVE BRZ, we teamed a Vortech V3Si with a Club DSPORT 2.25L to deliver 335 lb-ft of torque.

What We Like

In taking a critical assessment of the project to date, we are impressed with the power output, torque delivery and the character of the supercharger bypass noise. TheClub DSPORT FA225 engine has performed extremely well teamed with the Vortech V3 Si supercharger (once we got belt slippage under control). The vehicle is currently the highest horsepower supercharged BRZ/FR-S/86. The flat torque curve delivers between 300 and 335 ft-lbs of torque between 5,500 and 8,000RPM. This gentle curve is ideal for a transmission that has limited torque handling capabilities. It is also an ideal torque curve for maximum traction at the 500whp level. The unique and extreme bypass sound at idle from the Vortech V3 Si supercharger really helps this BRZ standout from the crowd.

The Club DSPORT FA225 engine has performed extremely well. The vehicle is currently the highest horsepower supercharged BRZ/FR-S/86.

While not as easy as pushing a button to change the boost on a turbo car, swapping the pulleys takes only about 5 minutes with the right tools. Changing the belt is closer to a 20 minute job, but very straightforward.

What We Don't Like

As we already mentioned, there is work to be done in the area of the exhaust system to quiet it down. Hopefully, we can find a solution that doesn't surrender too much horsepower. We also see the charge piping as a possible area to address to make it support a relocated and larger air filter and possibly an alternate routing.There is also some under-hood plumbing that we would like to clean up.

- – 237WHP Stock Vortech

- – 504WHP Vortech V3 Si

- – 562WHP Full-Race Turbo

The 500whp mark was not easy to hit, but we managed to get there. Peak boost was 25psi. On the turbo 2.1L, boost was at a higher 30psi. Can we crank up the boost on the Vortech? Unfortunately, it’s spinning as fast as it safely can.

Incorporating intercooling on centrifugal superchargers, along with adva nced engine controls and flex fuel, allow our 2.25-liter supercharged boxer engine to deliver more power to the ground than a $100,000 R35 GT-R.

The Bottom Line

Twenty years ago, a 5.0 Fox body Mustang with a Vortech supercharger was the standard by which all other modified vehicles were compared. With a good set of drag radials, these cars would typically run 12s in the quarter mile when properly set up. Today, the standards are higher, but technology makes yesterday's impossible possible today. Incorporating intercooling on centrifugal superchargers, along with advanced engine controls and flex fuel, allow our 2.25-liter supercharged boxer engine to deliver more power to the ground than a $100,000 R35 GT-R. That's a pretty impressive standard to achieve.

Adding Strength and Silence L.A.SLEEVE BRZ Finale

Text by Michael Ferrara -- Photos by Joe Singleton. Courtesy of DSport Magazine.

"WITH GREAT POWER, COMES GREAT RESPONSIBILITY." With the build of the L.A.SLEEVE BRZ, we have achieved great power. Over 500 horsepower at the wheels is triple the factory output. Hence it is our responsibility to see that the driveline is up to the task of supporting this additional power. It is also our responsibility to find a solution to manage the sound output. Currently, the sound levels would classify this BRZ as a weapon of mass distraction.

WHEN A VEHICLE THAT WAS ORIGINALLY SET-UP TO HANDLE 200 HORSEPOWER FROM THE FLYWHEEL IS NOW MAKING 600 HORSEPOWER AT THE FLYWHEEL, EVERY COMPONENT DOWNSTREAM OF THE CRANKSHAFT MAY NEED TO BE UPGRADED.

Driveline Upgrades

When a vehicle that was originally set-up to handle 200 horsepower from the flywheel is now making 600 horsepower at the flywheel, every component downstream of the crankshaft may need to be upgraded. Starting at the flywheel, we selected a McLeod Mag Force single-disc clutch and flywheel system to modulate the power delivery. This clutch is designed to handle the additional torque produced by aftermarket forced induction systems while still maintaining excellent clutch modulation. We found the driveability of the clutch to be very good and superior to most twin-disc solutions.

THE CLUTCH DISCS INSIDE THE KAAZ LIMITED-SLIP DIFFERENTIAL ARE WPC TREATED AT THE FACTORY TO ENSURE SMOOTH OPERATION AND A HASSLE-FREE BREAK-IN.

The transmission is the next component downstream of the clutch. While we expect that we will eventually need to upgrade the transmission in the future, we want to see if it will be able to handle the gentle torque curve of the Vortech supercharger. If and when we do upgrade the transmission, we are hoping that there are some more cost-effective and proven options available. Currently, both of the Holinger options are over $15K while the PPG gearset looks to be about an $8K investment. The kits that are being offered and developed to use the 350Z transmission look promising. We are looking into the available options and we will be testing one of these options on our turbo FR-S first.

The rear end was treated to a KAAZ clutch-type 1.5-way LSD upgrade and a set of 600whp axles from The Driveshaft Shop. These axles do not require upgraded hubs and simply bolt-in.

Between the tail of the transmission and the differential, we opted for the Drive Shaft Shop 1-piece carbon-fiber driveshaft. This propeller shaft is rated for 850whp and only weighs about half the weight (12.2 pounds) of the factory 2-piece driveshaft. Unlike the factory driveshaft that doesn't have serviceable U-joints, the heavy-duty U-joints on this driveshaft can be serviced or replaced as needed.

The OEM Torsen LSD was swapped out in favor of a KAAZ 1.5-way clutch-type LSD. The KAAZ is set up with enough preload to ensure that both wheels receive power, even if one wheel loses contact with the pavement. The clutch discs inside the KAAZ limited-slip differential are WPC treated at the factory to ensure smooth operation and a hassle-free break-in.

To take the power from the differential to the wheels, we selected a set of 600whp Level 2 axles from The DriveShaft Shop. These axles feature 300M material for the center bars along with chromoly outer CVs. The inner CVs are 108mm Porsche-style for high power handling. These axles are engineered to be direct bolt-ins. For applications needing power handling to a 1,000whp, The Driveshaft Shop offers Pro-level axles that require an upgrade of the hubs.

The Kaaz 1.5-way limited slip differential locks up both wheels on acceleration and can provide a more forgiving balance under engine braking than a full 2.0-way setup. It is a great selection for performance street cars.

Wheels & Tires

There are few companies that make the right size tire for the BRZ/FR-S platform. Ideally, a 245/35R18 would be the 18-inch tire that would give you the same tire height as the OEM tires. Unfortunately, the 245/35R18 offerings out there are limited or severely overpriced. We opted for the next best fitment. A set of 245/40R18 Nitto Tire NT05 were wrapped around 18x9.5 (+35mm) Enkei GTC01 RR wheels. The RR version is the lightweight version of the GTC01 wheel with a weight comparable to the venerable Enkei RPF1s. Weight on these wheels is just a fraction over 20 pounds.

Keeping it Cool

In addition to the Mishimoto oil cooler kit, we also installed a Mishimoto radiator and Mishimoto dual-12-inch fan and shroud kit. The radiator, fans and shroud fit extremely well and have been providing exceptional cooling on the street. We will eventually test them on the track to see their true capabilities.

IN ADDITION TO THE MISHIMOTO OIL COOLER KIT, WE ALSO INSTALLED A MISHIMOTO RADIATOR AND MISHIMOTO DUAL-12-INCH FAN AND SHROUD KIT.

To reduce engine temperatures, a Mishimoto aluminum radiator, slim profile fan and an oil cooler have been added for increased cooling capacity and thermal efficiency.

Added JDM

While the capabilities of the L.A.SLEEVE BRZ have been substantially increased, very little has been done in terms of improving the aesthetics. The Password JDM strut tower bar not only dresses the engine compartment, it also provides an ultra-rigid tie between the firewall and strut towers. The three-piece brace is manufactured from 6061-T6 aluminum while the rod-end connections are all 303-grade stainless-steel. Since the bras feature adjustable rod-end connections, a preload tension can be set to improve the response of the chassis.

Since our factory front-lip had seen much better days, we opted for a Password JDM dry-carbon 2-piece front splitter. This splitter accentuates the appearance of a wider stance while emphasizing the lines of the bumper and fenders.

The Sound Off

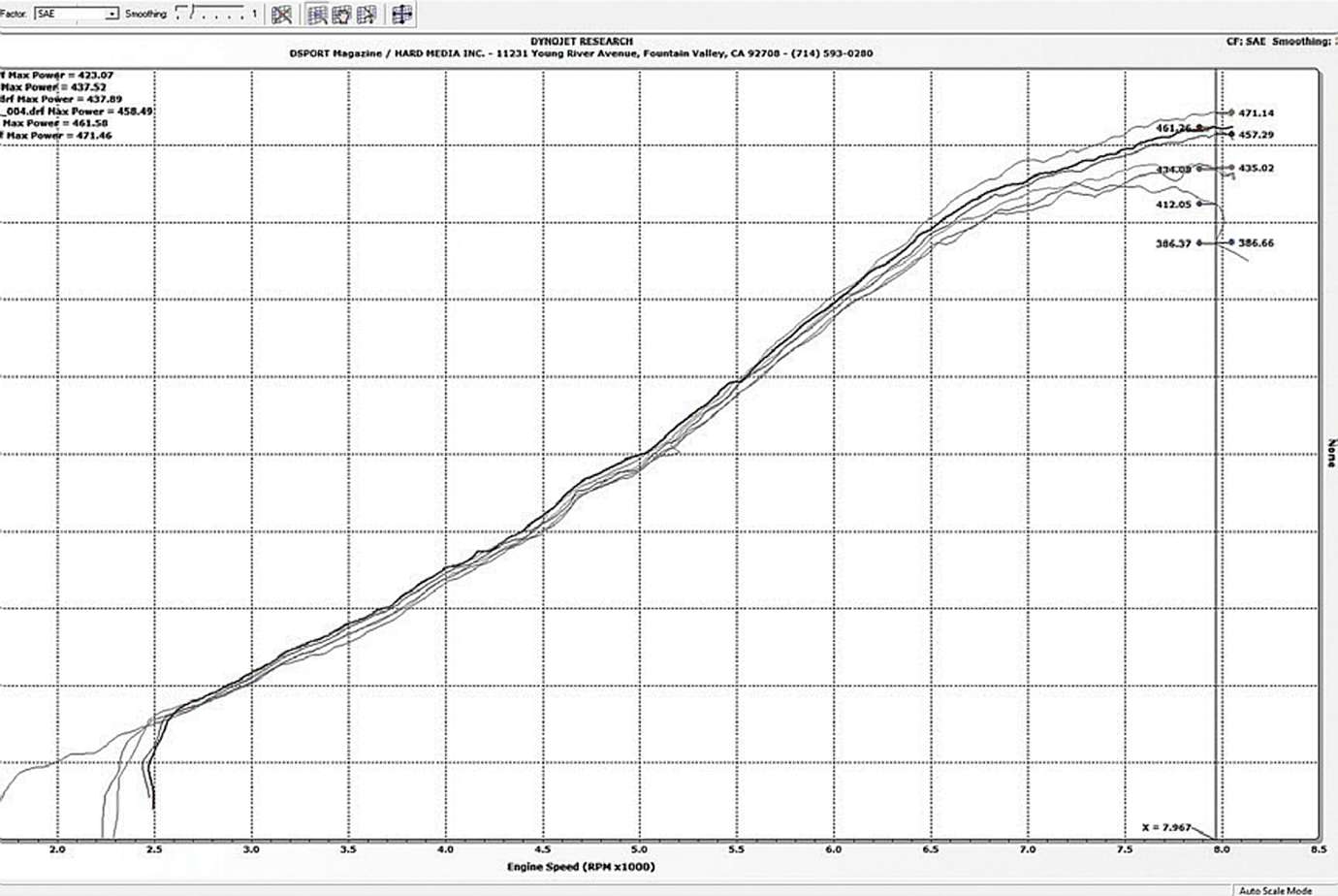

The 3-inch cat-back exhaust that we previously had on the vehicle has been moved over to our Turbo Project FR-S. It's a great match and the sound control is ideal for the turbo car. To find our ideal combination for sound management on the L.A.SLEEVE Project BRZ, we first put the entire factory exhaust back in place. We decided that we would dyno and sound test the vehicle as we added the BLOX Racing cat-back exhaust, BLOX Racing front and over pipes, and finally the BLOX Racing header. In this way, we would know which components added the most horsepower and the most sound level increases.

ON THE DYNO, THE BLOX CAT-BACK EXHAUST ALLOWED FOR AN ADDITIONAL 14 PEAK HORSEPOWER. AS FOR THE SOUND INCREASE, IDLE RUMBLE ONLY INCREASED TO 75DB.

The BLOX Racing cat-back system is made from 304-series stainless steel. Unlike many other exhausts for the BRZ/FR-S platform, the BLOX Racing system transitions from a single 61mm to a dual 51mm configuration right at the start. The dual 51mm pipes help to keep exhaust velocities and frequencies tuned so that no droning occurs. In fact, the exhaust is even quieter than OEM at certain engine speeds. For comparison, twin 51mm tubes have the same flow potential as a single 72mm pipe. So the system can support the same horsepower as a single 3-inch system, yet the sound control is superior. The quality of the system is top notch with thick 8mm CNC-machined flanges. Mandrel bends and TIG welding are utilized throughout. A set of adjustable 109mm oval tips finish the system off and allow it to fit just about any FR-S/BRZ bumper correctly. On the dyno, the BLOX cat-back exhaust allowed for an additional 14 peak horsepower.

- MAXIMUM HORSEPOWER

- 423.07 - Stock Exhaust

- 437.52 - Cat-Back Exhaust

- 437.89 - Cat-Back Exhaust + Test-Pipe

- 458.49 - Cat-Back + Header + Test-Pipe

- 461.58 - Cat-Back + Header + OEM Front Pipe

In an attempt to reach an acceptable sound level without sacrificing power, we ran various tests starting with the OEM exhaust, then added the BLOX Racing cat-back exhaust, test pipe and over-pipe and, finally the BLOX Racing header.

| SOUND DECIBEL TESTING |

|---|

| Stock Exhaust |

|

| Cat-Back Exhaust |

|

| Cat-Back Exhaust + Test-Pipe |

|

| Cat-Back + Header + Test-Pipe |

|

| Cat-Back + Header + OEM Front Pipe |

|

As for the sound increase, idle rumble only increased from 72 to 75dB. The sound increase at 5,000RPM was only +3dB, increasing from 94 to 97dB.

Next up, we decided to try the BLOX Racing test-pipe. Installing the test-pipe eliminates the main catalytic converter and a resonator. Hence, the test-pipe is only for racing use and must not be run on the street. While the elimination of the catalytic converter and the resonator made a slight increase at idle, raising from 75 to 77dB, the increase at 5,000RPM was much more dramatic. At 5,000RPM, sound levels increased from 97dB to 104dB. This would prove to be the single item that had the most dramatic increase on sound levels. Despite increasing the sound levels, the amount of additional power gained was minimal. Hence, this would only be a recommended upgrade if every last ounce of power is desired and noise control is not desired.

WE TEAMED THIS HEADER WITH THE BLOX RACING UP-PIPE TO ELIMINATE ALL TRACES OF THE FACTORY EXHAUST SYSTEM.

We next decided to add the BLOX Racing unequal-length header. This header features 1.75-inch primary tubes with a 4-into-1 design that culminates in a 2.25-inch collector. Again, 304-series stainless-steel is used along with CNC 8mm flanges. We teamed this header with the BLOX Racing up-pipe to eliminate all traces of the factory exhaust system. Since this header eliminates the factory pre-cats and since it doesn't have a CARB EO number, it is also intended only for off-highway racing use and must not be used on the street.

The Bottom Line

Sometimes you have to give a little to get a little. In the case of the L.A.SLEEVE BRZ, we were able to find an excellent combination of high-performance components that is delivering performance without compromise. The new exhaust system is substantially quieter yet delivering the same power as the previously way-too-loud setup. Now, the supercharger is louder than the exhaust. The significant amount of compressor bypass flow gives the vehicle plenty of personality. Everyone that hears the vehicle running wants a look under the hood for the source of the constant "whoosh." While we experienced some new challenges in this build, it is now Mission Accomplished.

DSport Magazine DSportmag.com