FA225sc: DSPORT’s Power Solution for L.A.SLEEVE’s BRZ

by L.A.SLEEVE

Text by Bassem Girgis—Photos by Joe Singleton. Courtesy of DSport Magazine.

TARGET: WORLD’S MOST POWERFUL SUPERCHARGED FA ENGINE

WHILE MANY HAVE ENCOUNTERED CHALLENGES WITH FA20D DEVELOPMENT, we’ve experienced the exact opposite. Our Club DSPORT FA21D (2.1-liter stroker variant) engines are thriving with turbocharged examples delivering over 560 horsepower to the wheels on E85 or Japanese premium pump gas (98 RON). In fact, Phoenix’s Power recently used one of the Club DSPORT FA21D short blocks in a street car to set the top speed record for an 86/BRZ in Japan. While the Club DSPORT FA21D engines use the original 86mm bore size (and no sleeves), Club DSPORT concurrently developed its FA225D engine program that features a sleeved 89mm bore size and the same 90mm stroke. With the custom L.A.SLEEVE amphibian sleeves in place, the power handling of the FA225D exceeds the FA21D (although that limit has yet to be found). The bigger, badder and better FA225 engine will also be receiving a big Vortech supercharger.

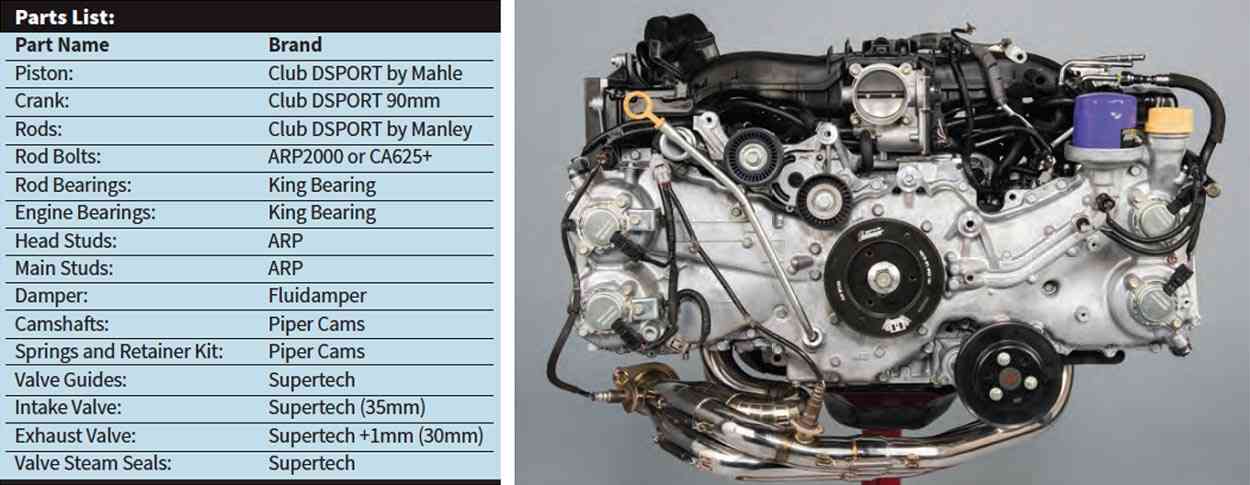

Custom amphibian sleeves from L.A.SLEEVE allow for an 89mm bore. The larger bore is filled by Club DSPORT E85-optimized pistons manufactured by Mahle. ARP fasteners are used to hold the case together at the elevated power levels. The right combination of parts along with precision machining and assembly deliver a powerful and reliable combination proving itself in all forms of competitive use.

Quick Recap

In part one of the L.A.SLEEVE BRZ demo car build, we upgraded the suspension and brake systems to complement the planned power increase. In the interest of high-speed handling and maneuverability, we adjusted the ride height to keep the car’s center of gravity low, equipped it with stiffer MAXG coilovers from Whiteline, replaced the soft factory bushings to reduce slop and flex, and added some more support to the chassis to minimize chassis flex. With the suspension upgrades in place, we installed an AP Racing Big Brake Kit by Stillen to maximize braking capabilities. With the suspension and brakes upgraded and ready to go, it was time we turn our attention to the powerplant that will become the most powerful supercharged FA engine ever.

Club DSPORT FA225sc

Unfortunately, there isn’t a week that goes by where we don’t hear about someone’s “built” FA20 horror story. Some of the major causes of an engine build failure include improper machining, cleaning, and assembly or simply using parts that were not properly engineered. There’s blown head gaskets, cracked pistons, high oil consumption and even broken camshafts. The excuses and “solutions” to what is sometimes a bad build or a bad tune are nothing short of comical. But it sucks to laugh at someone else’s expense. Fortunately, we’ve been on the other end of FA20 engine development with our engine packages exceeding our power and efficiency predictions. While we are still planning to push the boundaries, it’s safe to say that Club DSPORT has the 560-plus-horsepower FA engine combination figured out. Our solution doesn’t rely upon welded-up or machined closed decks, 14mm head studs or other “solutions” that seem to be causing more problems than they fix.

For the Club DSPORT FA225, L.A.SLEEVE manufactured custom thick-wall amphibious cylinder liners.

Engineering the Solutions

Our Publisher Michael Ferrara is a Mechanical and Aerospace engineer that’s been working with the top manufacturers in the performance aftermarket for the past 20 years. He’s already tackled the 4G63, 4B11, RB26, 2JZ, KA24 and SR20 in the past and he loves the challenge a new platform brings. Engine development is his passion. Having Master Machinist and F1-experienced Engine Assembler Magnus Ohlaker as part of the team has made unlocking the secrets of the FA20 platform a pretty straightforward affair. After all, few can claim to building over 400 Subaru EJ25 engines in their lifetime. For the FA20 development, Michael and Magnus looked for the weak links and opportunities presented in the platform. This is what led to the parts that Club DSPORT developed and selected for the Reference Series builds.

Machining & Assembly

One of the shortfalls in the Subaru engine is a lack of precision with regards to the machining process. While the level of precision is fine for stock power outputs, generating two to five times those levels requires a higher level of precision.

Nearly all Subaru boxer engines have a crankshaft centerline that simply isn’t straight in the block. As a result, the crankshaft lays to the left or the right or up or down at the front or the rear. This misalignment can place additional stress on the case halves at higher power levels. Since the amount of bearing surface area is relatively small, this can also accelerate bearing wear.

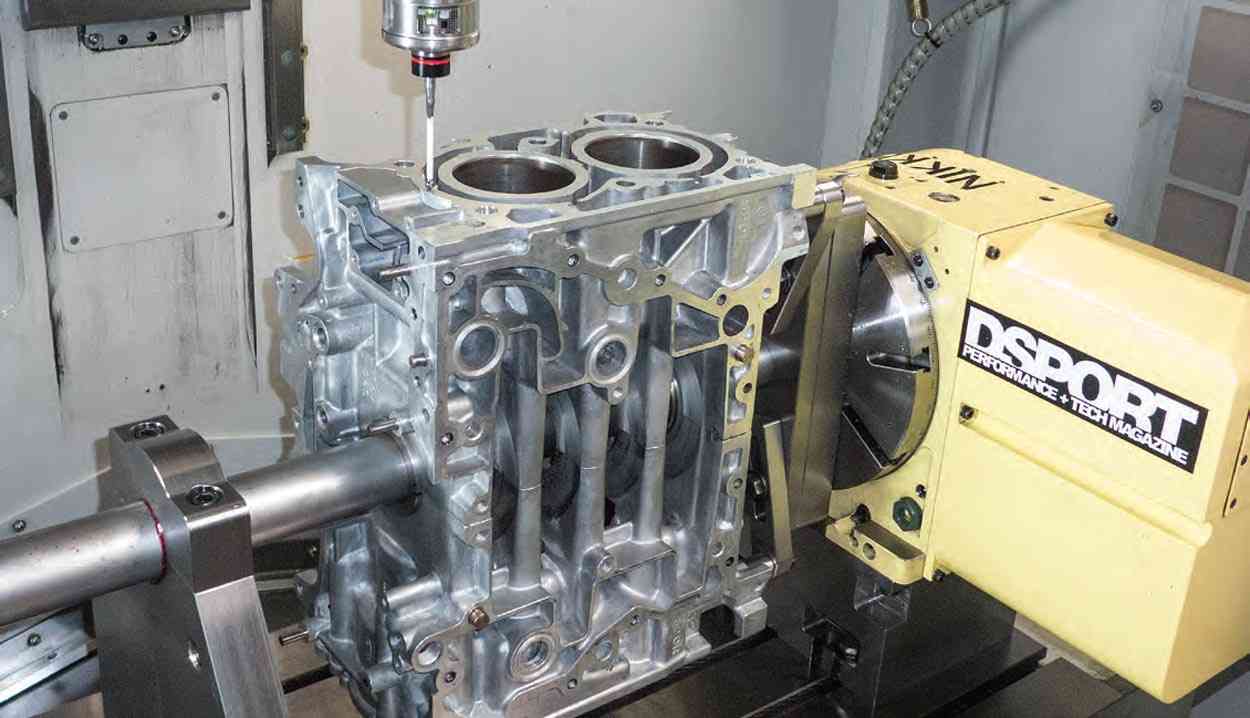

The first operation performed at Club DSPORT on all FA20 engine builds (new or reconditioned blocks) is to correct the main bore on the block. To accomplish this, both of the case halves are decked flat removing between 0.001”~0.002” (25-to-50 microns) on the CNC mill using a PCD insert. This process leaves a superior finish and allows for a new bore to be made at the tight tolerance of the OEM spec for the main housing bores. Once decking of the case halves is completed, the case is reassembled with ARP case bolts and torqued to the recommended spec. At this point, the assembly is placed on the Club DSPORT CNC line boring fixture where about two hours is spent to ensure that the engine case is lined up before the boring of the mains take place. A special PVD insert is used to machine the main bearing housing to leave a superior finish. Once the operation is completed, the case is taken apart so that the 2.0000-inch main bar can be installed with the precision main bore rings into the block. After this procedure, the block is ready to get some 4-axis CNC operations.

4-axis CNC Time

A probing operation is performed to establish the deck and cylinder locations of the block. As the block is on a rotary, it’s easy to rotate the block exactly 180 degrees to ensure that operations remain symmetric as needed. The first operation matches the deck heights of both sides of the block by taking the absolute minimum amount of material from the deck surfaces. This operation ensures that both banks of the block will have identical piston-to-deck clearances and compression ratios.

For a Club DSPORT FA21 engine, the process on the 4-axis CNC would be done, but when sleeving is to take place, the FA225 engine will have two separate visits to the 4-axis CNC. On the first visit, the OEM cylinders will be bored out to roughly 95.25mm to fit the new sleeves. The exact dimension depends on the exact dimension of the sleeves. The block will actually be bored slightly smaller than the OD of the sleeves. The smaller bore dimension in the block versus the outside diameter of the sleeve will provide an interference fit. The finish of the bore in the block is one area that can affect the success of the sleeving operation. The bore itself must be round and taper-free with a finish as smooth as possible. This is accomplished by running an optimized speed and feed with a PVD insert to cut the aluminum. Once all four cylinders have been bored at the exact locations, the block is one step closer to getting the sleeve installed so that they can be decked and bored to the target size.

Dry ice cools the ductile iron sleeves to -109° F, shrinking their size. As a result, they can be slipped into the heated 220° F engine block for a precise interference fit.

The bores are plateau honed for optimum surface profile and cylindrical roundness.

Engine sleeving is used as a method to either repair a damaged cylinder, increase the maximum bore size, or to simply strengthen the engine when higher power is desired. Our goal was to both increase the bore size (from 86 to 89mm) and to increase the strength of the cylinders. L.A.SLEEVE manufactures custom sleeves constructed from Moly 2000 ductile iron to fit any engine. With the added thickness and high strength of the sleeves, the engine can be pushed far past the factory specifications.

Fire & Ice

We chill the sleeves in dry ice to shrink their outer diameter, while heating the block to 220 °F to allow the bores to expand for a smooth installation of the sleeves. Once the sleeves were in place, we installed a torque plate to simulate the head, and torqued it to the correct specifications. A heat cycle regiment allows the sleeves to settle in their new home. The sleeved block is then placed back into the 4-axis CNC to be bored within a few thousandths of an inch of the final size while the sleeves are decked to their final height.

Finally, with the torque plate still in place, we honed the cylinder sleeves to the final dimension, with just a few tenths of a thousandths of an inch accuracy. The correct angle cross-hatch pattern and surface finish is critical for proper seating of the piston rings and cylinder lubrication.

With the sleeves installed and bored in the cylinders, they are decked to achieve the final height.

Bottoms Up: The Right Parts

For the Club DSPORT FA225 builds, we source brand-new FA20D bare blocks from Heuberger Subaru of Colorado Springs, Colorado. These blocks go through a number of machining operations before the custom L.A.SLEEVE amphibious sleeves are installed. To fill the sleeves, the pistons were engineered in cooperation with Mahle Motorsports. Machined from M142 forged aluminum alloy, the greater strength, lighter weight and thermal stability of the forging is ideal for high-performance and extended durability. The pistons have a revised compression height and ring package location to compensate for the 90mm stroke crankshaft and custom rod length. The piston’s top ring grooves are hard-anodized, which protects against micro-welding and further increases the pistons’ strength and resistance to failure of the ring land. The pistons go through a triple-coating process with a phosphate dry film to protect the pin bores from galling, as well as having Mahle’s proprietary anti-friction coating applied to the skirts. With the higher temperatures and pressure in the cylinders from the boosted engine, it is crucial for the piston to be strong and durable without adding unnecessary mass. The secret to the exceptional combustion performance from these pistons lies in the geometry of the piston dome. Since Mahle is the piston supplier to a number of OEMs that manufacture direct-injection engines, they are no strangers to the geometries that can deliver exceptional performance and reduce the likelihood of detonation. The pistons yield a final static compression ratio between 10.8~11.0:1 on BRZ/FR-S/86 engines or an 11.0~11.2 compression ratio on WRX FA20 engines (due to the smaller combustion chamber on the turbo cylinder heads).

A quality bearing is imperative when building a high-output engine, both for performance and longevity. For these reasons we chose King Racing Bearings. To absorb vibration and protect the crankshaft, we installed a Fluidamper harmonic damper.

The ARP case bolts are constructed from 8740 chrome moly. The performance studs are required to ensure the case halves don’t shift under higher power, which can cause bearing or crankshaft wear.

Since the Club DSPORT FA21 and FA225 engine packages use a Club DSPORT-spec forged-steel 90mm stroke (+4mm longer than stock) crankshaft, a connecting rod needed to be engineered with new measurements and the power handling capability of 1,000whp. Club DSPORT engineers worked with Manley Performance to produce a custom Turbo-Tuff 4340-alloy, USA-manufactured custom high-performance rod as the solution. This rod features ARP rod bolts and the unique cap design present on FA20 engines. The design of the rods maximizes the strength without requiring any clearancing of the engine block. ARP also provides the solution for the high-performance fasteners used for the case and the cylinder head.

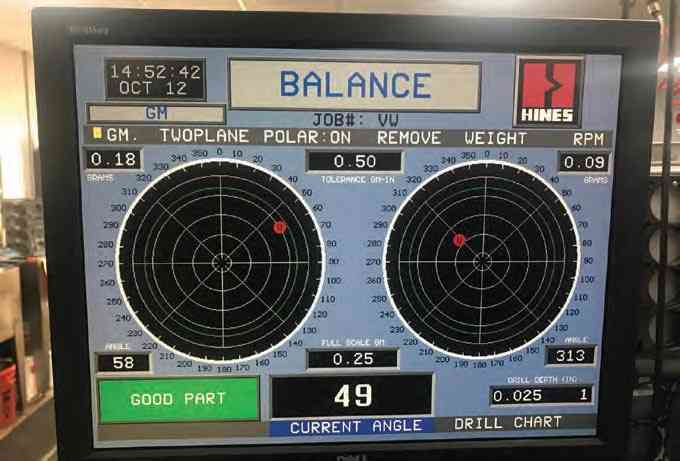

In the interest of maintaining a proper equilibrium, we balanced our crankshaft, pistons, pins, and rods in a dynamic three-stage balancing process to within 0.25 grams. As an engine’s speed increases, any imbalance is magnified; the force exerted on the main bearings is relative to the RPM of the engine squared. Balancing the reciprocating and rotating mass reduces vibration and increases the lifespan and power output of the engine.

A three-angle valve job was completed before the installation of the Supertech valves and a set of Piper Cams springs. The heads, sourced from Heuberger Subaru, were then attached using an ARP head stud kit.

Top-End: Heads, Cams & Valvetrain

The camshafts are responsible for the opening and the closing of the valves, which means they control the air, fuel (from port system), and exhaust flow going in and out of the engine. To optimize volumetric efficiency, we selected Piper Cams BP285 bumpsticks (Stage 3). These camshafts are designed for the ultimate road/track day car, which made them the perfect fit for L.A.SLEEVE’s demo-car. They offer a cam profile that delivers mid-range torque and top-end power, without sacrificing the idle and low-load characteristics needed on a mild-mannered street car. The camshafts work collaboratively with a spring and retainer kit from Piper Cams. Even the smallest component can play a huge role in an engine’s performance. The valvetrain can be a major factor in regards to an engine’s airflow, mixture quality, and high RPM efficiency. The design, shape, and seat angle of a performance valve is engineered to maximize the flow and velocity of the gases going in and out of the combustion chamber. The valve is only open for a brief moment, then it must snap shut to form an effective seal. We chose Supertech intake and exhaust valves to help us reach our goal. The intake valves are stainless steel with a black nitride coating that hardens the surface of the valve. The exhaust valves are constructed from inconel 751 alloy steel. The light weight and extreme heat-handling characteristics are ideal for our soon-to-be supercharged application. Only the exhaust side requires the higher heat-handling characteristics of the inconel alloy. The heads were ported at Club DSPORT to eliminate any additional restrictions in the airflow before a fully-radiused valve job was performed on the Newen.

The Subaru boxer engine is a horizontally-opposed configuration with the cylinders placed on opposite sides of the crankshaft in two separate case halves.

It’s Almost Time

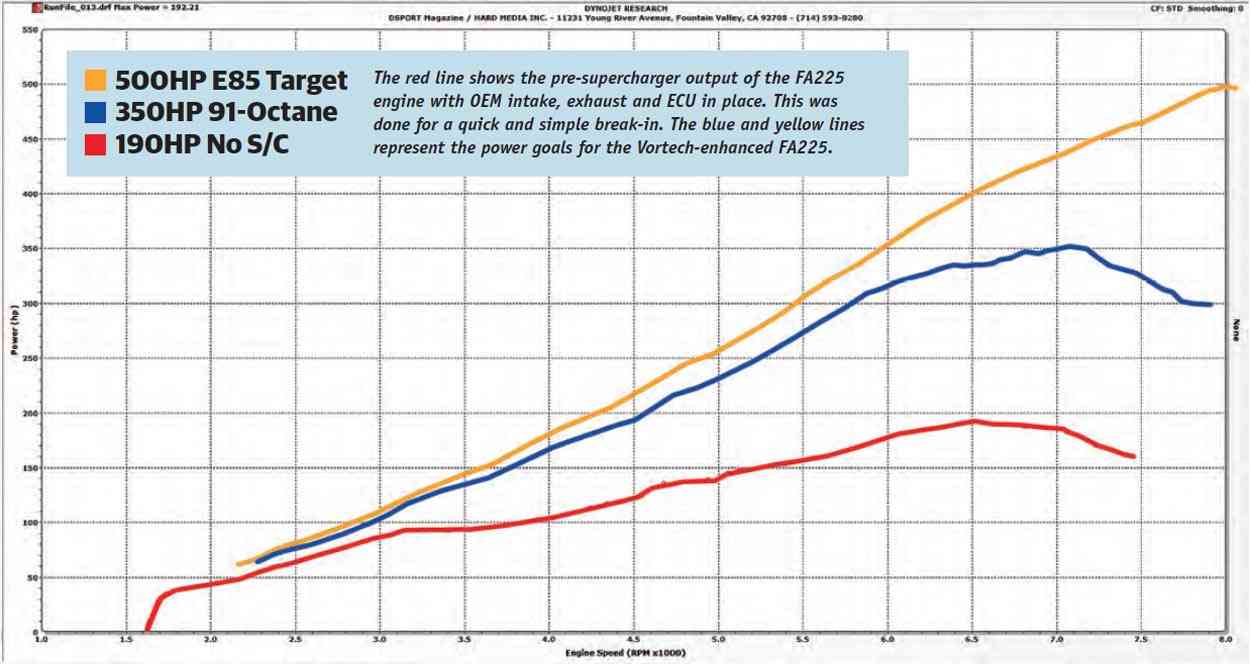

With our FA225 completed, installed and broken-in (without the supercharger in place), we have netted 190 horsepower to the wheels with all of the factory components in place (headers, exhaust system, intake, etc.). Next, we look forward to the addition of the blower and complementary items, like the fuel system, the cooling system, and the flex-fuel electronics. Our target is to make over 350whp on 91-octane and to hit 500whp on E85. If we can do it, we will hold the title of world’s most powerful supercharged FA engine. If you’ve ever felt like the BRZ is a bit underpowered, L.A.SLEEVE’s demo-car will most certainly change your mind.

From DSport Magazine, April 2018 #192